|

Reverse Osmosis / Ultra high pressure reverse osmosis (UHP-RO) |

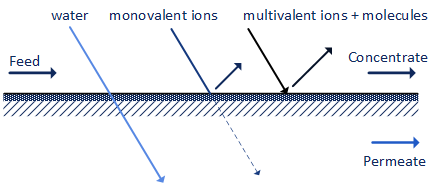

Reverse osmosis is a pressure operated membrane process in which the smallest molecules as well as polyvalent and monovalent ions are almost completely separated from a solution. Modern reverse osmosis membranes have a retention of 99.5 - 99.8 % based on a 2000 ppm NaCl solution.

|

|

Reverse osmosis works analogous to nanofiltration by transport through diffusion over a dense membrane. Water can diffuse through the membrane, but ions are almost completely retained. The pressure required to force the water through the membrane is directly dependent on the osmotic pressure of the solution, which in turn depends on the salt concentration in the solution.

OSMO offers high pressure reverse osmosis systems with a system pressure of up to 160 bar!

The pressure of standard systems for the treatment of well or brackish water is approx. 16 bar. In contrast, seawater plants are operated at up to 80 bar. The operating pressure of a high pressure reverse osmosis is usually about 120 bar. This makes it possible to concentrate many solutions to near their solubility limit.

Our typical applications for Reverse Chromosis / High Pressure Reverse Osmosis are:

- Desalination of well water / process water / drinking water

- Concentration of salts and organic solutions

- Recycling of waste water

- Treatment of acids

Separate the best from the rest - Individual process combinations for highest efficiency

Solutions can be desalinated by reverse osmosis. By combining the process with an upstream ultrafiltration, river water can also be used for the desalination process. If the salt concentration achieved by reverse osmosis is not sufficient, an ion exchanger can also be connected downstream to separate the remaining salts.

OSMO Faktor-X - Maximum recovery for your reverse osmosis

Reverse osmosis plants for well and brackish water are operated with a yield of approx. 75 - 80 %. Thus, usually 20 - 25 % of the supplied water is discharged into the wastewater. If drinking water is used for the operation of the reverse osmosis, there are high purchase costs and disposal fees. With the OSMO Factor X, we have developed a system with which the yield can be increased economically to over 90 %, thus more than halving the waste water produced.

Ultra high pressure reverse osmosis (UHP-RO) - Maximum concentration for maximum efficiency

For waste water with a high salt load or solutions which have to be concentrated, high-pressure reverse osmosis is used. By this it is possible to reduce waste water and to return valuable resources back into your process (Minimum Liquid Discharge / MLD ; Zero Liquid Discharge / ZLD).

The right support in every stage of the project

We have gained experience with a variety of different process fluids. We would be pleased to assist you as a plant engineering company in the selection of the suitable membrane and the optimal process control! For special applications, we are also happy to offer you the possibility of process screening in our laboratory with subsequent industrial piloting as part of our 4 steps 2 separation!